Four reasons to choose Leitz Edgebanding Solutions

Four reasons to choose Leitz Edgebanding Solutions

Seeing is believing, and visitors to Professional Woodworking Expo (PWE) 2026 will be able to witness high-performance edgebanding tools from tooling experts Leitz Tooling UK. We asked Leitz’s Marketing Manager, Ben Mitchell, to explain why visitors looking at edgebanding should make a bee line to Leitz stand K51 at the new look show next year.

Here’s Ben’s top four reasons to visit Leitz for edgebanding solutions:

1. Solutions for managing varying thicknesses and profiles

The award winning FlexTrim3 profile cutter from Leitz was engineered to reduce downtime from profile changes when edgebanding. The Leitz FlexTrim profile cutters allow simple profile changes via the machine control on Homag machines. These unique cutters contain up to 3 profiles in one tool. Resulting in reduced downtime from changing and setting tools. The tool is very flexible and is designed to use customer specific profiles, allowing for bespoke manufacturing at a large scale.

Leitz tooling also manufactures adjustable jointing cutters that allow for a significant reduction in downtime and adjustments when changing thicknesses between batches. Leitz adjustable jointing cutters reduce downtime from tool changes and also reduce the amount of tool stock that furniture manufacturers need to hold, which has reduced tooling set up costs for some companies by up to 60%. The easy adjustment system allows for faster changes to the cutting depth between batches. Additionally, the high-grade diamond tips enable smooth finishes, ideal for glueing and significantly reduces tear out thanks to the tooth geometry.

2. Solutions for High Quality Finishes

Leitz has specialised tooling solutions for refining surface finish quality. Leitz offer a high sheer range of edgebanding tools called EdgeExpert. Edge Expert tools cut at the optimal cutting angle for high quality finishes at 74°, which after heavy research was proven to provide better finishes than higher sheer tooling. With innovative tooth geometries, EdgeExpert tooling provides impressive tear- and chip-free edges and smooth sides, even when processing laminated or denser materials. In fact, EdgeExpert tools achieve about 30% longer lifetime when cutting laminates compared to conventional solutions.

3. Solutions For Mass Production

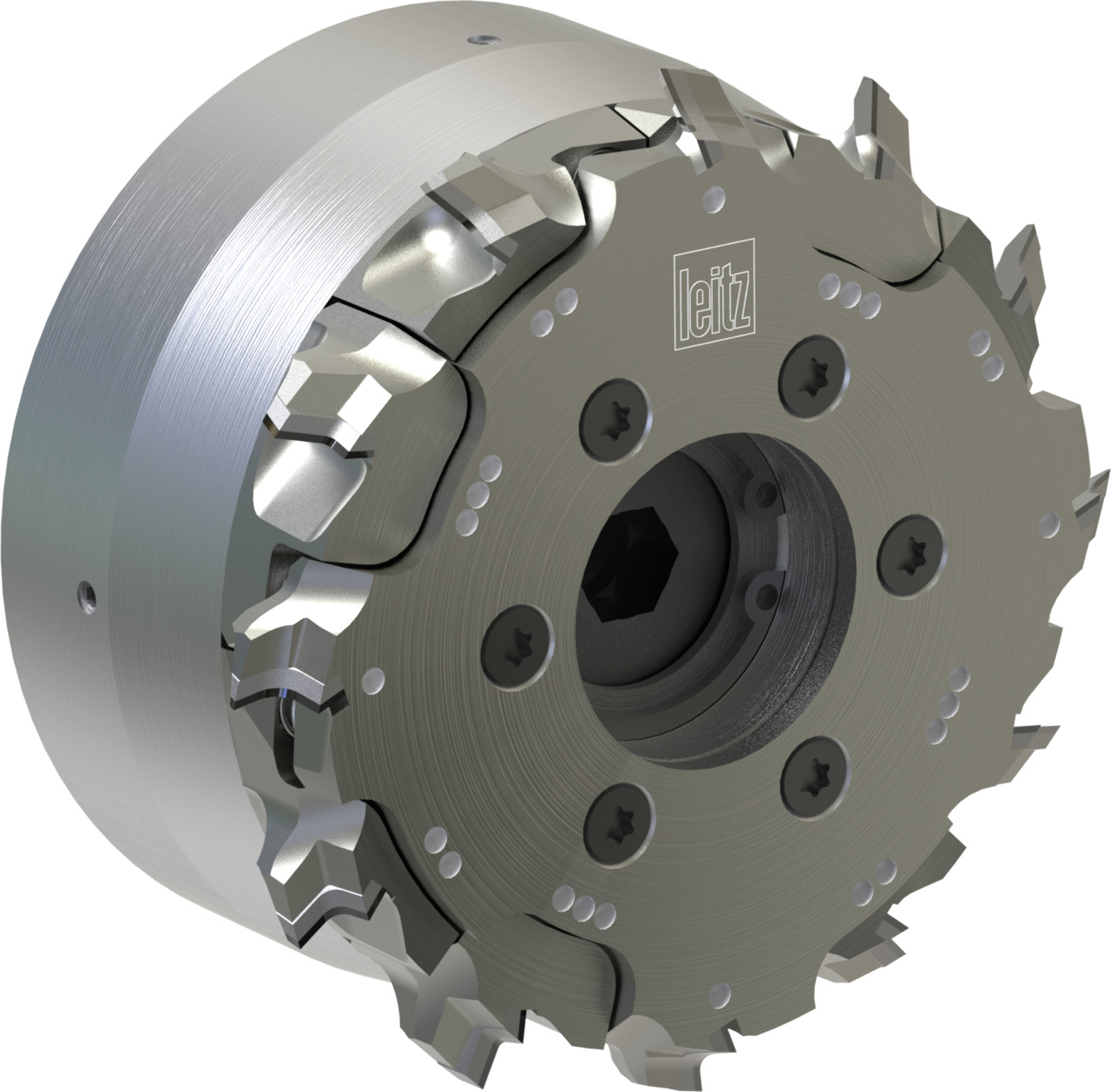

Leitz works with many of the UK’s largest furniture and kitchen manufacturers and therefore has created some devoted solutions for mass producers. Products like the DP hogger are suitable for the wide variety of carrier and decorative materials used in panel production. The hogger has a recommended feed rate of 30 m min-1, making it suitable for mass manufacturing. Thanks to the new tooth shape, optimum machining results are achieved over the entire life cycle of the tool which can reduce machining costs by up to 20%. The design enables efficient chip removal and the vibration-reducing tool body further increase the tool life and thus the economic efficiency. The DT premium hogger can also be sharpened up to 15 times, making it extremely sustainable and cost effective with a consistent cutting width.

4. Solutions For Noise Reduction & Dust Extraction

The processing of panel material requires light and quiet tools at the same time in order to minimise the damage to man and machine as far as possible. The Diamaster WhisperCut series of edgebanding tools from Leitz is specially designed to reduce such strains. Due to its optimised body shape and low weight, noise pollution during jointing and rebating is significantly reduced by up to 5 dB(A) and the quality of the workplace is improved. The large sharpening area of the system with replaceable cutting edges also guarantees high-cost efficiency, resulting in low costs per running metre.

Leitz also supplies Dust Flow Control (DFC) hoods for edgebanding tools. Leitz DFC Extraction hoods are individually designed and precisely adapted to the application. Therefore, all processing options such as profile variants or different material thicknesses are taken into account. The results being extensive cost savings through improved cutting, extended tool life, the reduction of cleaning at the machine and dust-free workpieces. Not only does the DFC technology create less machine wear, maintenance, set-up and energy costs. But it also can help produce -5 dB(A) less noise through noise-reducing design of the Extraction hood. When combined with WhisperCut technology, this provides significant noise reduction in edgebanding.

To learn more about these innovative edgebanding solutions, to get a free consultation or for technical advice, contact Leitz today or visit them on stand K51 at PWE26.

For more information, visit: Precision tools and tooling systems | Leitz

Or contact: Contact-uk@leitz.org

01279 454530

More news

CRASH Christmas Message Launched to Make a Difference

Advanced Machinery Services (AMS) Returns for PWE 2026